Product Description

Product Description

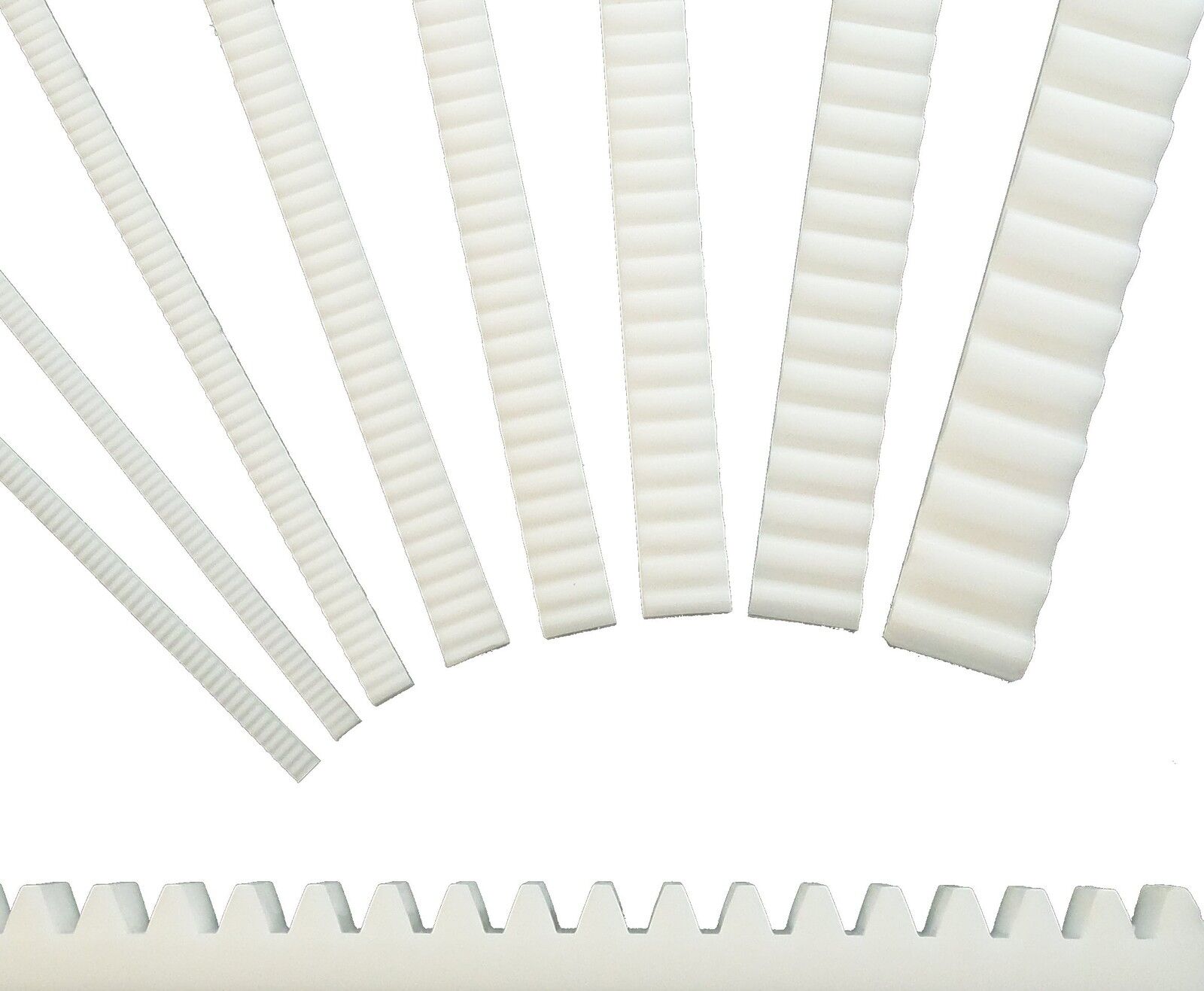

Nylon Gear Rack

made of nylon and has steel bar inside,used for sliding gate.

It normally works with Gate Motor.

We have 2 Eyes Light, 2 Eyes Heavy,4 Eyes Light and 6 Eyes Heavy.

Each piece of nylon gear rack has screws as pictures show below,

Our products are exported to Southeast Asia, Europe, South America, etc. Reliable quality

You are warmly welcome to send us an inquiry for detailed information.

| Product Name | Specification | Modulus | Material |

| Nylon Rack | 2 Eyes Light | M4 | PA66 |

| Nylon Rack | 2 Eyes Heavy | M4 | PA66 |

| Nylon Rack | 4 Eyes Light | M4 | PA66 |

| Nylon Rack | 6 Eyes Heavy | M4 | PA66 |

| Iron Rack | 8*30*1005 | M4 | Q235 |

| Iron Rack | 8*30*1998 | M4 | Q235 |

| Iron Rack | 9*30*1005 | M4 | Q235 |

| Iron Rack | 10*30*1005 | M4 | Q235 |

| Iron Rack | 10*30*1998 | M4 | Q235 |

| Iron Rack | 11*30*1005 | M4 | Q235 |

| Iron Rack | 11*30*1998 | M4 | Q235 |

| Iron Rack | 12*30*1005 | M4 | Q235 |

| Iron Rack | 12*30*1998 | M4 | Q235 |

| Iron Rack | 22*22*1005 | M4 | Q235 |

| Iron Rack | 22*22*1998 | M4 | Q235 |

| Iron Rack | 30*30*998 | M6 | Q235 |

| Iron Rack | 30*30*1998 | M6 | Q235 |

Company Profile

Main Products

Production Process

Packaging & Shipping

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Sliding Door Accessories |

|---|---|

| Material: | Nylon and Iron Steel |

| Modulus: | M4 |

| Delivery: | 2~7 Days for Stock, 15~45 Days for Without Stock |

| Feature: | Oil-Resistant, Corrosion-Resistant, Heat-Resistant |

| Color: | Black |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What safety considerations should be kept in mind when working with plastic gear racks?

When working with plastic gear racks, several safety considerations should be kept in mind to ensure the well-being of operators, prevent accidents, and maintain the integrity of the equipment. Here’s a detailed explanation of the safety considerations associated with plastic gear racks:

- Proper Installation: Ensure that plastic gear racks are installed correctly and securely according to the manufacturer’s instructions. Improper installation can lead to misalignment, excessive wear, or premature failure, posing safety risks. Follow the recommended torque values and fastening procedures to ensure the gear rack is properly mounted and aligned with other components.

- Load Capacity: Be aware of the load capacity limitations of the plastic gear rack. Exceeding the recommended load capacity can lead to gear failure or unexpected accidents. Consider the anticipated loads and forces in the application and select a gear rack that can safely handle those requirements. If necessary, consult with the manufacturer or an engineer to ensure the gear rack is appropriately sized for the intended application.

- Operating Speed: Take into account the operating speed limitations of the plastic gear rack. High-speed applications can generate significant centrifugal forces and heat, potentially compromising the integrity of the gear rack. Ensure that the selected gear rack is suitable for the intended operating speed range and consider additional measures such as lubrication or cooling if required.

- Maintenance and Inspection: Regularly inspect and maintain plastic gear racks to ensure their continued safe operation. Check for signs of wear, damage, or deformation, including tooth wear, cracks, or excessive backlash. Perform routine lubrication as recommended by the manufacturer. Replace any worn or damaged gear racks promptly to prevent unexpected failures that could lead to accidents or equipment damage.

- Environmental Considerations: Consider the environmental conditions in which the plastic gear rack will operate. Extreme temperatures, excessive humidity, or exposure to corrosive substances can degrade the performance and integrity of the gear rack. Select a plastic material that is suitable for the anticipated environmental conditions and ensure any necessary protective measures are in place to prevent deterioration or failure.

- Operator Training: Provide proper training to operators working with machinery or equipment that incorporates plastic gear racks. Ensure they understand the potential hazards, safety protocols, and procedures for safe operation, maintenance, and inspection of the gear racks. Promote a culture of safety and encourage operators to report any concerns or issues promptly.

It’s essential to adhere to relevant safety standards, regulations, and guidelines specific to the industry and application when working with plastic gear racks. Consulting with experts, such as engineers or safety professionals, can provide valuable insights and help ensure compliance with safety requirements.

Can plastic gear racks be employed in food processing and packaging machinery?

Yes, plastic gear racks can be successfully employed in food processing and packaging machinery, offering several advantages in this specific application. Here’s a detailed explanation of why plastic gear racks are suitable for use in food processing and packaging machinery:

- Food Grade Materials: Plastic gear racks can be manufactured using food-grade materials that comply with industry regulations and standards for contact with food. These materials, such as certain types of nylon or acetal, are specifically formulated to be safe for use in food processing and packaging applications. They are non-toxic, non-reactive, and do not leach harmful substances into the food products, ensuring the highest level of food safety.

- Corrosion Resistance: Plastic gear racks are inherently resistant to corrosion, making them suitable for the often harsh and corrosive environments encountered in food processing and packaging machinery. They can withstand exposure to moisture, cleaning agents, and food acids without degrading or corroding. This resistance to corrosion helps maintain the hygiene and functionality of the gear rack, ensuring long-term reliability and performance.

- Smooth and Hygienic Surfaces: Plastic gear racks can be manufactured with smooth surfaces, minimizing the accumulation of food particles, debris, or contaminants. The absence of surface irregularities, such as pits or scratches commonly found in metal gear racks, makes them easier to clean and sterilize. Smooth and hygienic surfaces are crucial in food processing and packaging machinery to prevent bacterial growth, maintain product integrity, and comply with strict hygiene standards.

- Low Friction and Self-Lubrication: Plastic gear racks exhibit low friction characteristics, reducing wear and energy consumption in food processing and packaging machinery. They can operate smoothly and efficiently, even without extensive lubrication. Some plastic materials used in gear racks have self-lubricating properties, further minimizing the need for frequent lubrication and preventing the risk of lubricants contaminating the food products.

- Noise Reduction: Plastic gear racks offer quieter operation compared to metal gear racks. The non-metallic construction of plastic gear racks helps dampen vibrations and noise transmission, contributing to a quieter working environment in food processing and packaging facilities where noise reduction is desirable.

- Design Flexibility: Plastic gear racks can be molded into various shapes and sizes, allowing for design flexibility in food processing and packaging machinery. They can be customized to meet specific application requirements, including load capacity, precision, and dimensional constraints. Plastic gear racks can integrate seamlessly into the overall design of the machinery, optimizing performance and functionality.

When employing plastic gear racks in food processing and packaging machinery, it’s important to select materials that comply with food safety regulations and standards. Consulting with gear rack manufacturers or suppliers who specialize in food-grade materials can ensure the appropriate selection of plastic gear racks for these specific applications.

What is a plastic gear rack, and how is it used in machinery?

A plastic gear rack is a type of gear rack that is made from plastic materials, such as nylon, polyacetal (POM), or polyethylene (PE). It is designed to provide a lightweight, cost-effective, and versatile solution for motion control applications in machinery. Here’s a detailed explanation of what a plastic gear rack is and how it is used in machinery:

A plastic gear rack consists of a linear gear strip with teeth along its length, similar to a traditional gear rack made of metal. However, the use of plastic materials offers several advantages in terms of weight, cost, corrosion resistance, and noise reduction. Plastic gear racks are commonly used in various machinery applications, including:

- Automation Systems: Plastic gear racks are utilized in automation systems, such as linear actuators or robotic motion control systems. They provide a lightweight and cost-effective solution for converting rotary motion into linear motion or vice versa. By meshing with a pinion gear or a similar mechanism, the gear rack enables precise and controlled linear movement, allowing for tasks such as part feeding, assembly, or material handling in automated machinery.

- Printing and Packaging Machinery: Plastic gear racks find applications in printing presses and packaging machinery. They are used for linear motion control, such as paper transport, registration, or cutting operations. Plastic gear racks offer advantages such as reduced noise, lightweight construction, and resistance to corrosion from ink or other fluids. Their use in printing and packaging machinery ensures smooth and reliable operation, contributing to efficient production processes.

- Medical Equipment: Plastic gear racks are commonly employed in medical equipment and devices. They are used in applications such as adjustable hospital beds, dental chairs, or diagnostic equipment. Plastic gear racks provide quiet operation, lightweight design, and resistance to sterilization processes. These features make them suitable for medical equipment where precise linear motion control is required, ensuring patient comfort, ease of use, and accurate positioning.

- Office Equipment: Plastic gear racks are used in various office equipment, including printers, scanners, or photocopiers. They contribute to the movement of scanning heads, paper feeds, or other components requiring linear motion control. Plastic gear racks offer advantages such as low friction, quiet operation, and cost-effectiveness. Their integration into office equipment ensures reliable performance and accurate document handling.

- Consumer Electronics: Plastic gear racks are found in consumer electronics devices that involve linear motion control, such as cameras, camcorders, or 3D printers. They enable precise positioning, focusing, or movement of components within these devices. Plastic gear racks provide lightweight and compact solutions, allowing for miniaturization and portability in consumer electronics products.

Plastic gear racks offer a range of benefits in machinery applications, including their lightweight construction, corrosion resistance, cost-effectiveness, and noise reduction. However, it’s important to note that plastic gear racks may have limitations in terms of load capacity, thermal resistance, or durability compared to metal gear racks. Therefore, the selection of a plastic gear rack should consider the specific requirements and operating conditions of the machinery application to ensure optimal performance and longevity.

editor by Dream 2024-05-06