Plastic Gear Rack Production Schedule

Introduction

Plastic gear rack production schedule is a crucial aspect in the manufacturing of plastic gear racks. The production schedule ensures efficient and timely production of these essential components. Plastic gear racks play a significant role in various industries, such as automotive, food processing, agriculture, medical equipment, and 3D printing. Understanding the production schedule and its relationship with plastic gear racks is essential for maintaining a smooth manufacturing process.

Informational Connection

The plastic gear rack production schedule is closely linked to the production and quality of plastic gear racks. By following a well-planned production schedule, manufacturers can ensure that each step in the manufacturing process is executed efficiently. This ensures that the final product meets the required standards and specifications. The production schedule also considers factors such as material selection, design optimization, and quality control, which are crucial in producing high-quality plastic gear racks.

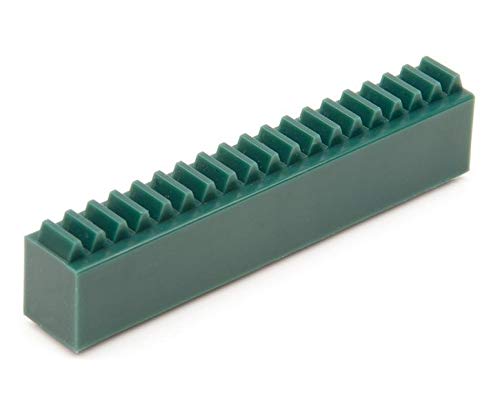

Performance Characteristics

Plastic gear racks possess several performance characteristics that make them highly suitable for various applications. These characteristics include high strength, corrosion resistance, low friction, and excellent wear resistance. The use of plastic gear racks in different industries is advantageous due to their ability to withstand harsh environments, provide smooth and efficient operation, and reduce maintenance requirements.

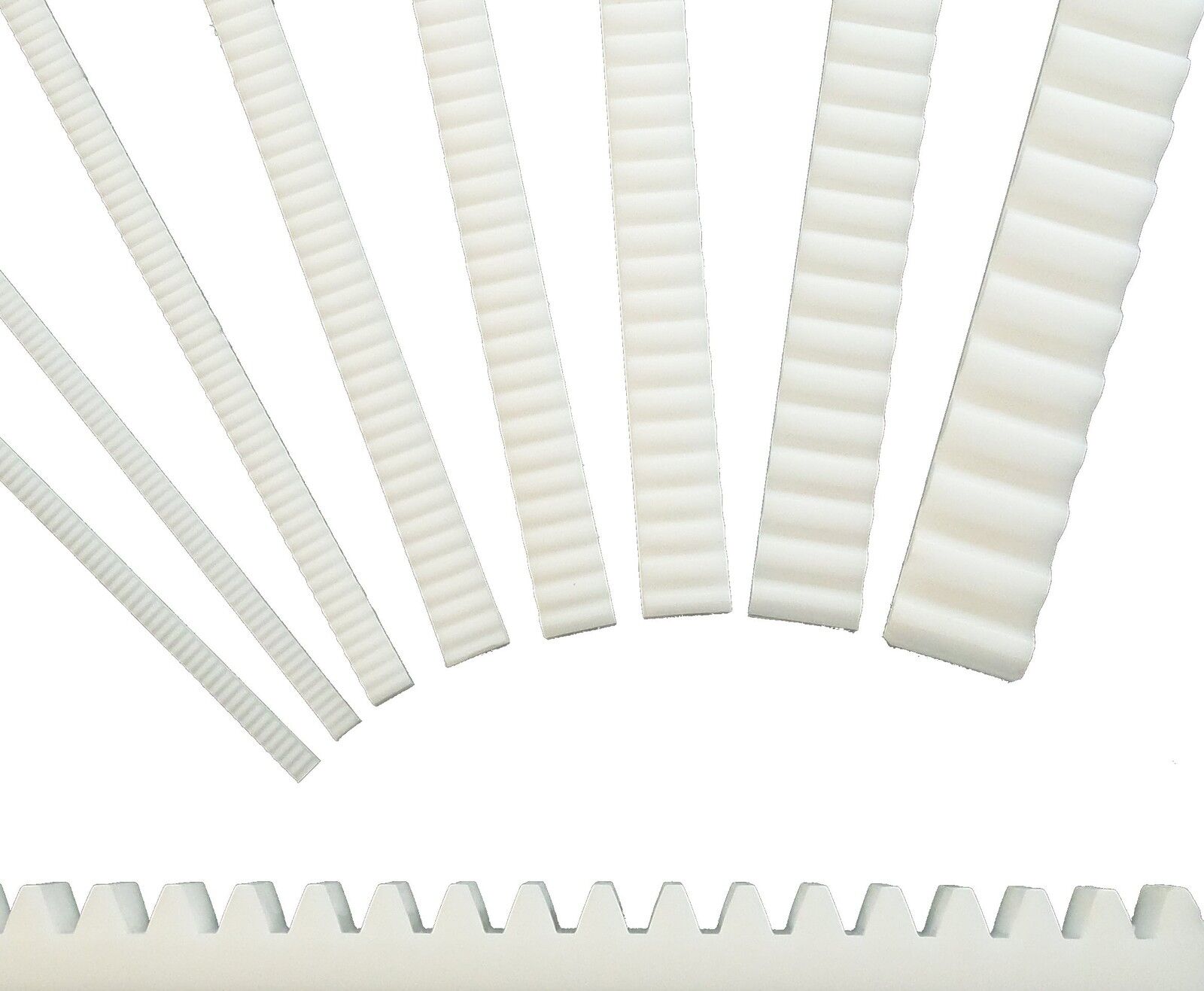

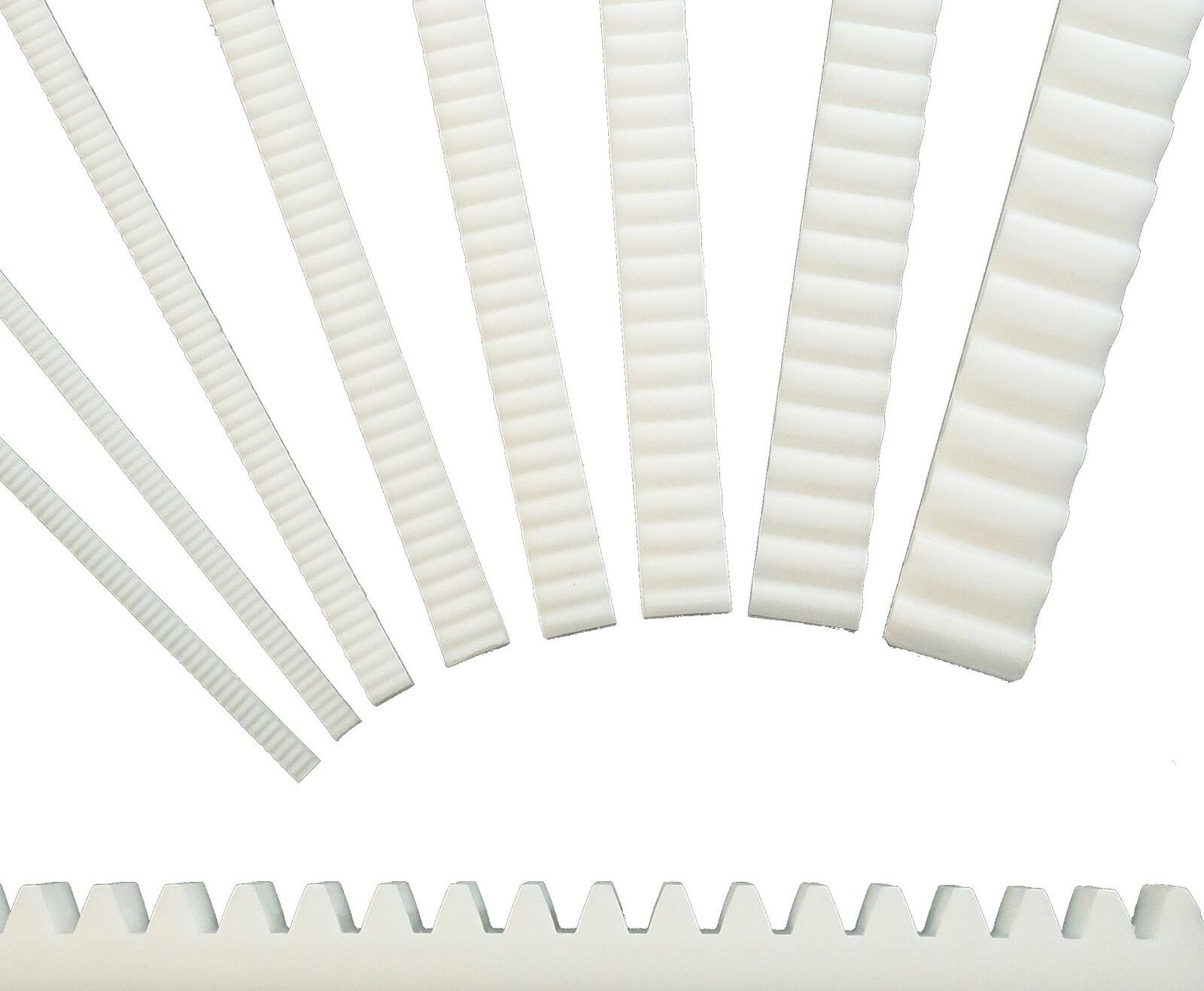

Types and Advantages

Plastic gear racks come in different types, each with its own unique characteristics. Common types include polyoxymethylene (POM), polyamide (PA), and polyethylene (PE) gear racks. POM gear racks offer high stiffness and excellent dimensional stability. PA gear racks have good self-lubricating properties and high impact resistance. PE gear racks are known for their chemical resistance and low friction coefficient. These different types of plastic gear racks provide manufacturers with options to choose according to specific application requirements, ensuring optimal performance.

Application

Plastic gear racks find extensive use in various industries, including food processing, agricultural machinery, automotive industry, medical equipment, and 3D printers. In the food processing industry, plastic gear racks are employed in conveyor systems, ensuring smooth movement of products during production. In agriculture, gear racks are used in machinery for efficient movement and operation. The automotive industry utilizes plastic gear racks in various components, such as power steering systems. Medical equipment relies on plastic gear racks for precise movement in devices like robotic surgical systems. Additionally, plastic gear racks are utilized in 3D printers to control the movement of printing heads accurately.

Future Development and Opportunities

The future of plastic gear rack production is promising, with several opportunities for growth. The increasing demand for lightweight and durable components in various industries will drive the demand for plastic gear racks. Advancements in materials and manufacturing technologies will further enhance the performance and capabilities of plastic gear racks. To tap into the potential opportunities, it is crucial for manufacturers to stay updated with the latest industry trends, invest in research and development, and explore collaborations with other industry players.

Choosing the Right Plastic Gear Rack

Selecting the appropriate plastic gear rack involves considering various factors. Firstly, it is essential to determine the specific requirements of the application, such as load capacity and operating conditions. Secondly, material selection plays a vital role in ensuring the gear rack’s performance and durability. Design optimization should also be considered to maximize efficiency and reduce noise. Additionally, working with reliable suppliers who can provide high-quality gear racks and offer excellent after-sales services is crucial. Lastly, cost-effectiveness and quality control measures should be taken into account to ensure the best value for money.

Maintenance of Plastic Gear Rack

Proper maintenance of plastic gear racks is essential to ensure their longevity and optimal performance. Regular equipment inspections help identify any potential issues or wear and tear. Cleaning and corrosion prevention are crucial to protect the gear rack from environmental factors. Lubrication and regular maintenance of moving parts ensure smooth operation. When necessary, replacing worn-out components is crucial to maintain the gear rack’s performance. Continuous improvement and upgrading of gear rack systems can also enhance their efficiency and durability.

Why Choose Us

Choosing our company for your plastic gear rack needs offers several advantages. Firstly, we are a specialized manufacturer and supplier of plastic gear racks with extensive industry experience. Our products are manufactured using high-quality materials and advanced production techniques, ensuring superior performance and durability. Additionally, our company is committed to providing excellent customer service, including prompt responses to inquiries, timely deliveries, and comprehensive after-sales support. By choosing us, you can benefit from our expertise, reliability, and the assurance of receiving top-notch plastic gear racks for your specific requirements.

Our products and company offer the following advantages:

- 1. High-Quality Materials: Our plastic gear racks are manufactured using top-grade materials, ensuring durability and performance.

- 2. Precision Engineering: Each gear rack is meticulously engineered to provide precise and efficient operation.

- 3. Customization Options: We offer customization services to meet specific requirements and ensure optimal compatibility with different applications.

- 4. Stringent Quality Control: Our gear racks undergo rigorous quality control measures to ensure they meet the highest standards.

- 5. Competitive Pricing: We offer competitive pricing for our premium-quality plastic gear racks, providing excellent value for our customers.

Q&A

Q1. What are the advantages of using plastic gear racks in the automotive industry?

A1. Plastic gear racks offer lightweight construction, corrosion resistance, and low noise operation, making them ideal for automotive applications that require efficient and reliable power transmission.

Q2. Can plastic gear racks withstand harsh working environments in the food processing industry?

A2. Yes, plastic gear racks are designed to withstand challenging conditions, including exposure to moisture, chemicals, and frequent cleaning, making them suitable for food processing applications.

Q3. How can I ensure the proper maintenance of plastic gear racks?

A3. Regular inspections, cleaning, lubrication, and timely replacement of worn-out parts are essential for the maintenance of plastic gear racks. Following the manufacturer’s guidelines and recommendations is crucial.

Q4. What is the future outlook for plastic gear rack production?

A4. The future of plastic gear rack production is promising, driven by the growing demand for lightweight and durable components across industries. Advancements in materials and manufacturing technologies will further enhance the performance and capabilities of plastic gear racks.

Q5. How can I benefit from choosing your company for plastic gear rack procurement?

A5. By choosing our company, you can benefit from our extensive industry experience, high-quality products, customization options, stringent quality control, competitive pricing, and excellent customer service. We strive to meet and exceed our customers’ expectations.

Author: Dream